In most cases project schedules become unworkable and untrue reflection of the project status. Usually the reasons are: –

- Changes in design

- Client changes

- External unforeseen circumstances e.g. inclement weather, strikes etc.

- Poor performing sub-contractors.

- The programme incorrectly sequenced with/or unrealistic durations.

Therefore before the project commences, it’s essential that the programme is correctly sequenced with realistic durations, understood and committed by all those involved. However, in the real world projects become delayed due a compounding effect of small trivial matters committed by all parties (including the client). Even the most smallest of delays e.g. deliveries and held up in traffic repeated over time will have an overall effect.

Should the programme be disrupted due to a poor performing sub-contractor then tactful methods to commence succeeding tasks on time must be challenged. The project manager and defaulting sub-contractor will need to identify those tasks are delaying and disrupting the program and agree when those tasks will be completed. It’s essential to meet and agree with the defaulting sub-contractor and other sub-contractors what tasks can continue or start as planned and which will be delayed. Basically, the defaulting contractor will need do all they can to ensure, succeeding tasks do start as planned. If this is achieved, then the delayed tasks will have little or no effect on the succeeding tasks and in theory the programme will gradually recover. Even if succeeding critical path tasks start on time. Also it’s important that the defaulting sub-contractor are made aware of the possible financial implications their performance is having to other sub-contractors. Basically, the programme should not be adjusted unless the disruption is so severe that it affects many tasks or the completion date. If this happens then a recovery program will have to be developed and issued to all the subcontractors.

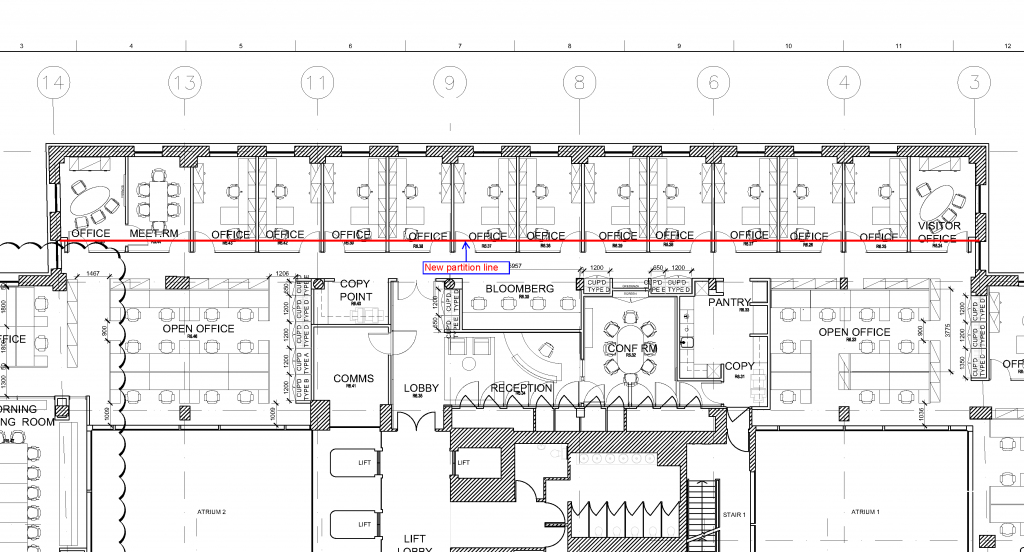

When changes are made by the client the planner will need to demonstrate if the change will have an implication to the critical path. In my ebook How to Write Construction Programmes & Schedules I explain how the critical path is illustrated on a bar chart. So let’s presume we’re 50% through a office fit out project and the client has issued a change request, requesting the office cross walls* to be altered to increase the width of the adjacent corridor. The red line shown on the drawing below illustrates where the client wants the dry lining ‘cross walls’ to end.

However the client hasn’t formally instructed the change, he’s simply requested to know the cost and programme implications before formally instructing the variation. So before replying the planner will need carry out the following:-

Step 1 – Assess the status of the the work completed and on going locally in the area.

Step 2 – Assess and decide which construction elements are effected by the proposed change.

Step 3 – Discuss with the sub-contractors the duration to alter their works and agree the earliest time they can commence the change. It’s important to remind sub-contractors that the client has simply requested the implications – not an instruction to alter or stop works. All works should continue unless instructed otherwise.

Step 4 – Plan the sequence of the works and adjust the construction programme.

It’s imperative that the all tasks are linked before re-scheduling. All decent project software like Asta, MS project have this facility, otherwise you be spending hours having to move each task separately with a risk of errors occurring.

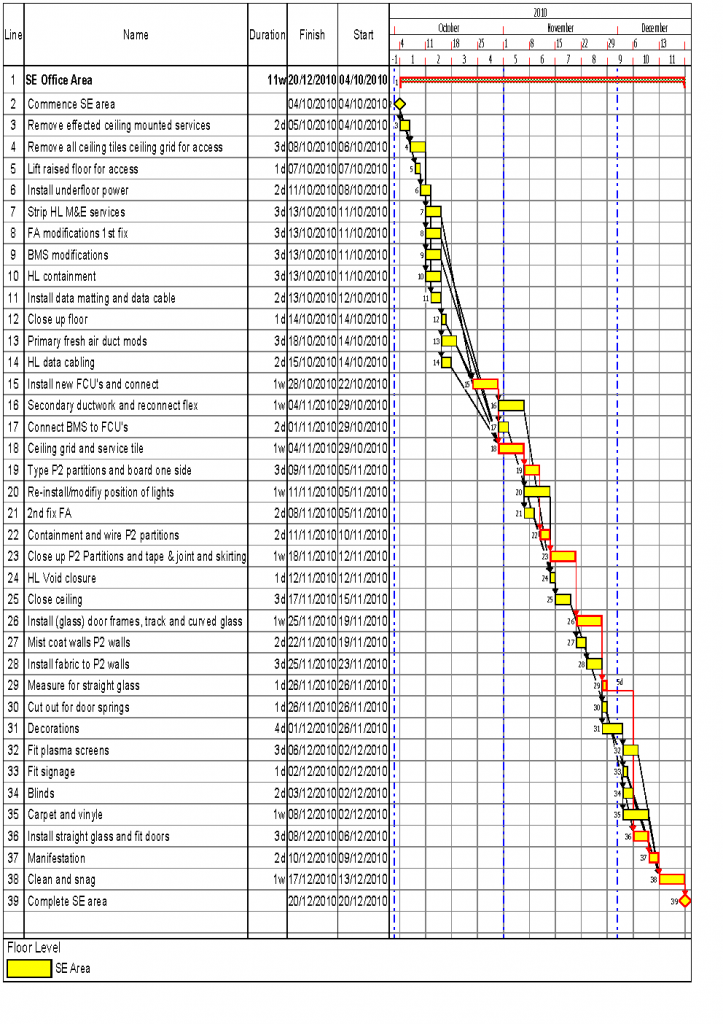

Prior to any changes the current programme is shown below:-

Using the steps above the following findings and considerations were made:-

Step 1. – The cross wall were set out, built and boarded one side with electrical containment being installed. high level 1st fix M & E works were complete and ceiling grid installed with service tiles.

Step 2 – Dry lining – Walls to cut back,

Ceiling – Replace ceiling tiles that now have fixing holes exposed,

Electrical – Relocate containment within wall,

Electrical – Move ceiling modular lights one tile further into office. Possible clash with other services

Step 3

Drylining – 2 days extended duration and can start immediately.

Ceiling – 1 day and can exchange ceiling tiles immediately.

Electrical – 1 day and can start immediately

Step 4

The sequence will be as follows:-

Relocate containment (1 day) – Cut back partitioning (2 days) Replace tiles (0)

An increase to the programme of 3 days.

Now I turn to the software and make the necessary changes. Let’s assume that the client emailed the request on Thursday 11th November. The next day we replied in the morning with our revised programme showing the implications the change will have – assuming the works commence on the Monday 15th November. Looking at the programme you will notice I’ve split containment within P2 partitions (item 22) with the additional 1 day segment commencing on the 15th November. This is the additional containment work. Next I link that task down to a new task modification to cross walls (item 23) then link that task to close up walls (item 24). The end date has now moved out from the 20th December to the 23rd December. The reason, is that the critical path has been extended. Should the change be to a non-critical itemsthen the total duration would may have remained. We understood that that the end date was important to the client so we recommended that the client paid for affected works to be carried out during the weekend to mitigate the end date being delayed. As a result the client agreed with our recommendation and close up P2 partitions item 24 was carried out during the weekend 20th-21st November which brought the works back to the original completion date.

In addition to showing the changes to the programme I also show the chanes in a different colour and include the programme in the project report.

In addition to showing the changes to the programme I also show the chanes in a different colour and include the programme in the project report.

*The cross walls are built from top of raised floor to underside of ceiling. The partition head track is fixed to ceiling tiles.